A Guide to Medical Gas Testing Services and Validations

Medical gas systems play a critical role in patient care, supplying oxygen, nitrous oxide, medical air and other life-supporting gases to various departments across healthcare facilities. As such, maintaining the integrity and safety of these systems is non-negotiable. Routine medical gas testing service and validation ensure that medical gas pipeline systems are operating within the strict limits defined by regulatory standards such as HTM 02-01, and help prevent issues before they become safety risks.

Regular medical gas testing services isn’t just a tick-box exercise—it’s essential for patient safety and operational continuity. It verifies that flow rates, pressures and quality of gas meet required specifications, while also identifying potential issues such as contamination, leaks or pipeline degradation. Without scheduled medical gas testing services in place, healthcare providers risk non-compliance, inefficiencies and potential harm to patients relying on critical care services.

What’s Involved in Medical Gas Testing Procedures

Validation of a medical gas pipeline system involves a series of technical inspections and tests that ensure the system is compliant, safe and functional across its full network. These checks are required at several key stages: post-installation, following modifications, or during scheduled maintenance.

Key components of the validation process include:

- Pressure Medical Gas Testing Services to confirm the system maintains adequate and stable pressure levels across all outlets.

- Flow rate verification to ensure gases are delivered at the correct rate required for various medical procedures.

- Gas purity analysis to confirm the absence of contaminants or incorrect gas mixtures.

- Alarm system checks to validate that alerts and monitoring equipment are functioning as intended.

- Outlet and valve testing to verify the performance and reliability of terminal units and isolation points.

- Cross-connection testing to ensure there is no risk of gas lines being incorrectly linked or mislabelled.

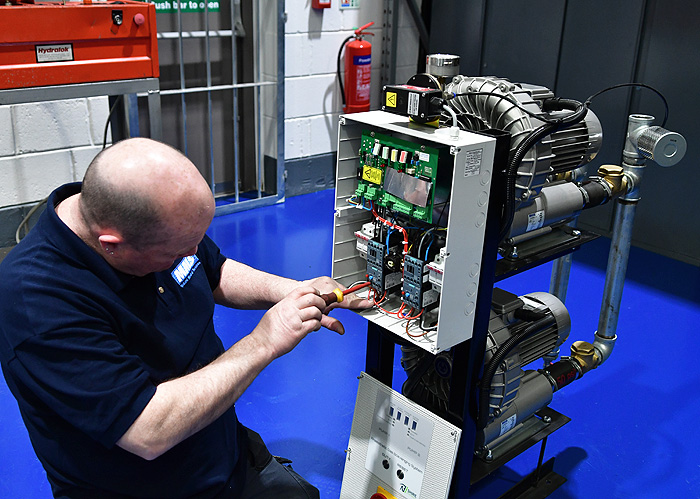

Each test must be carried out by a qualified and experienced technician using calibrated equipment and following the guidelines set out by HTM 02-01 and the relevant British Standards.

Why Validation is Critical for Medical Gas Testing Requirements

Failing to meet compliance requirements can have serious consequences, ranging from regulatory penalties to patient harm. Healthcare facilities are required to provide assurance that their systems have been tested, validated and documented at regular intervals. This process not only supports internal safety protocols but is also essential for passing inspections by regulatory bodies such as the Care Quality Commission (CQC).

Routine validation also offers long-term operational benefits. It helps identify wear, inefficiencies or faults early, reducing unplanned downtime and costly repairs. It ensures gas delivery remains consistent during high-demand periods and supports better planning of system upgrades or expansions.

At Midland Medical Services, we support healthcare providers with full compliance medical gas testing services and validation services, carried out by experienced specialists who understand the critical nature of medical gas systems. From initial system commissioning to routine inspections, we ensure your facility stays safe, efficient and regulation-ready.